Winter Maintenance Program

Save Time. Save Money.

Winter maintenance = summer electrical reliability.

The facilities we provide preventative maintenance, we find many items that need correction and fix them by the outline of the following scope of work:

- Inspect and correct terminations.

a. Color of the wire.

b. Correct torque.

c. Inspected the power supplies, neutrals and grounding.

e. Insulation checks on SOW, GGC cord, grounding and motor terminations.

2. Circuit breakers and contactors.

a. Open the contactors and inspect the contacts. Recondition them and mate them to each other.

b. Look for temperature signatures.

c. Check setting on circuit breaker.

3. Overload, torque leads, check and adjust settings to nameplate information and multipliers allowed by NEC Code.

4. Refurbish.

a. Have the tools and cleaners for contacts, wire, and controls terms.

b. Install electrical grease.

c. Replace contacts that are close to failure, wire and cord as needed.

This list (not complete) should be performed by an experienced electrical personnel that has experience with torque, circuit breaker, contactor rebuild and ground. The facilities that have had this done, have experienced excellent reliability.

Gregg Buchl

CESI

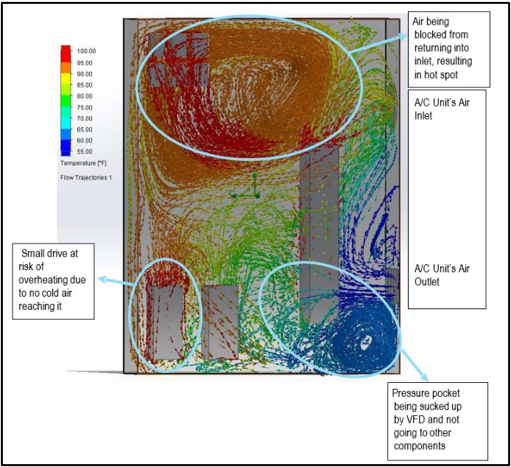

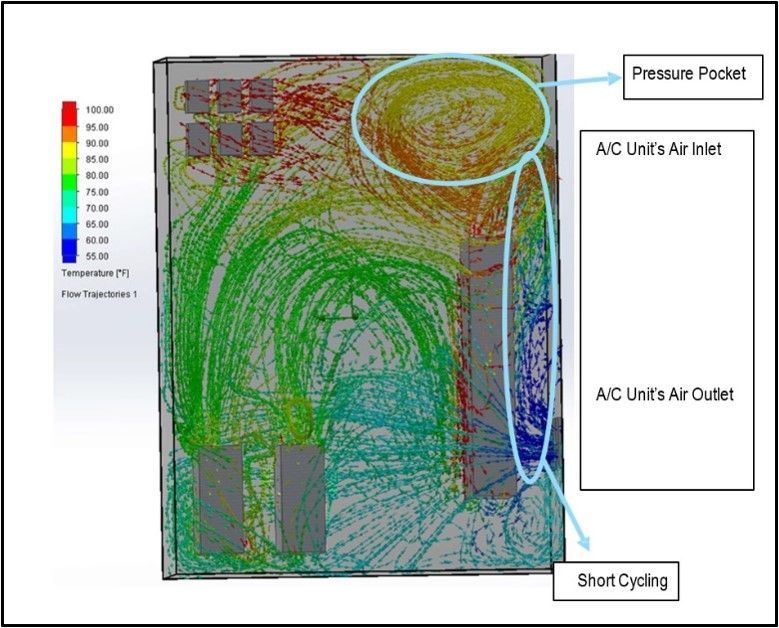

Let your enclosure breathe in cool air - CESI has found that intgegrating in breather vents, fans or an A/C unit.

SIMPLE VENTALATION CAN MINIMIZE HEAT & CORROSION FROM TRAPPED MOISTURE.