AGGREGATE AUTOMATION

Operation controls, plant monitoring and radio controls.

Automation & Controls

CESI is an Industrial Electrical OEM Contractor here to serve you! We have history developing products and systems derived from production inefficiencies that are proven and presently working. We use relay-logic and interlocking procedures to ensure your have reliable control of your facility.

Tell us about your operation! Let us go to work for you. Get connected with someone that can express your ideas onto paper and make it a reality with CESI!

Radio Controls

Communications equipment that allows you to operate machinery from the inside of your front-end loader, tower or operations room.

Want to control a pump from miles away? Start, stop, control conveyor speed, travel, raise and lower stackers, and anything else you would like to control remotely in the hands of one man.

Click the icon to view a past jobs.

Radio Controls

Communications equipment that allows you to operate machinery from the inside of your front-end loader, tower or operations room. Start, stop, control conveyor speed, travel, raise and lower stackers and anything else you would like to control remotely in the hands of one man.

Click the icon to view a past jobs.

MinuteMan Monitoring

Monitoring systems by the use of CT's and alert communications. Replace motors, belts and associated field equipment before it wears down and fails you while your running!

Minimize downtime of unexpected replacement of parts and equipment. Get on top of your systems operations and, avoid unexpected expenditures. Schedule shutdowns and replacements instead.

Etheridge Automation

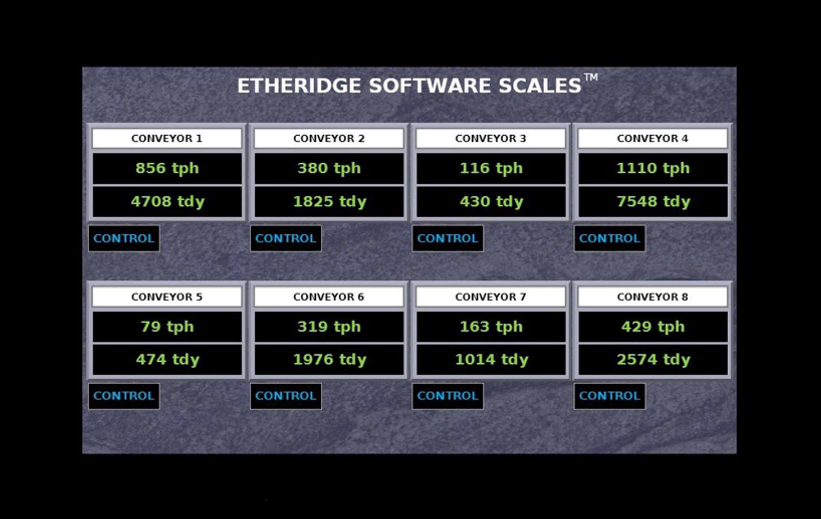

CESI is an Exclusive Sales Representative for Etheridge Automation in the state of Colorado for Plug-In Automation Systems™, Etheridge Software Scales™, Etheridge Software Speed Switches™.

The aggregate industry is driven by efficient production, and the measurement of tonnage produced is one of the most important tools to monitor and improve operations. The most used tool to measure production today, the load cell-based belt scale, is a design that has numerous maintenance costs and inherent inaccuracies. Etheridge Software Scales™ developed an alternative to load-cell based conveyor scales. They are designed to be installed in the motor starter of the conveyor, with no electrical components outside of the MCC and no moving parts whatsoever.

Benefits to the Software Scale™ design include:

- Ease of installation – no parts or wiring to install on the conveyor

- Automatic calibration

- No moving parts and no maintenance

- Easily transferrable from one conveyor to another

- Accuracy is not compromised over time

WHAT CUSTOMERS HAVE TO SAY

"They are consistent and durable. Running for 4+ years now. If you’re looking automation with ease, Software Scales has made our operations easier over the years.“

Erik A., Iowa

“We like them because, no moving parts. Very little error once calibrated correctly. Initial calibration is more involved. Once dialed in, they are maintenance free compared to traditional belt scale. Important note: must reinitialize the calibration process if you change any components mechanical like motor, belt, etc. or, the angle of the conveyor.”

Dan S., Michigan

“We are very happy with scales in the correct application. Recommendation is to use on a level of conveyor, offers more consistent compared to a stacker and slacking conveyor belts. Think about it, if the differential load and energy build up do not match, you get misleading amps. Easy maintenance and calibration was quick. Right fit for the right application like, standalones.”

Peter M., Ohio

“The scales are good as long as the belt has some incline. If it is a flat belt or, goes up and down over small hills they're misleading. As a Process Control Engineer, I like the simplicity of the scale working off of the amps of the motor. I researched these scales myself when all other scales at the time were not quite Ethernet compatible. Overall, we have been pleased with them and their ability to have 8 scales on one scale head.”

Mike V., California

What solutions can CESI bring you today?

What solutions can CESI bring you today?

Tell us what project you would like to get started on and we’ll send you a quote.

Tell us what project you would like to get started on and we’ll send you a quote.

ABOUT US

CESI

is different from your average electrician in that we offer integrated solutions. Bridging concept and design. We are established with the aggregate industry, controlling 480VAC 3-phase systems with 120VAC. New facilities, retro-fit or, expansion of existing facilities. We have history, developing products and systems derived from production inefficiencies that are proven and presently working.

LINKS

Copyright 2021 Colorado Equipment Systems Integration, Inc. All Rights Reserved. Web Design by Site Spartan